Energy Manager simplifies electricity monitoring by tracking electricity usage in real time and identifying opportunities to minimise waste and emissions by up to 30%.

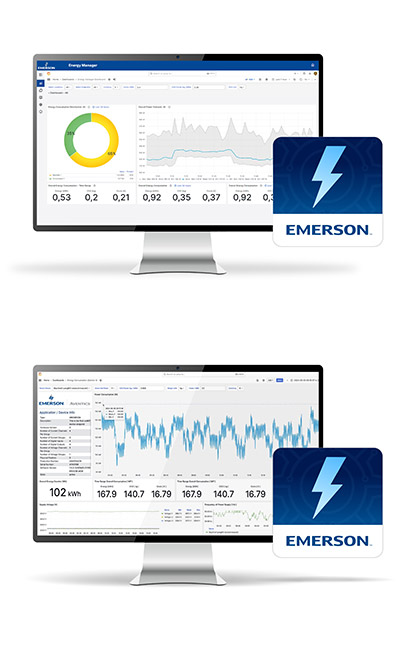

Emerson has launched its new Energy Manager solution, a pre-engineered hardware and software offering designed to simplify industrial electricity monitoring with quick setup and intuitive operation. The Energy Manager solution comes out-of-the-box and monitors asset energy usage in real time, enabling manufacturers to gain deeper insights into energy consumption and operating costs, reducing carbon dioxide (CO2) emissions and optimising energy and operational efficiency.

Most manufacturers, including original and industrial equipment manufacturers, consumer packaged goods companies and food and beverage producers, are under increasing pressure to increase productivity while reducing energy use and environmental impact. However, industrial machinery is energy-intensive and consumes a lot of energy even when idle. To best meet efficiency and sustainability goals, operators must have the best possible visibility into energy use in their facilities to address waste and inefficiencies.

This level of visibility gives organisations greater control for identifying idle machines and optimising machine schedules for off-peak hours, reducing electricity usage throughout the facility and significantly cutting overall utility costs. Most facilities can reduce energy waste by up to 10-30% and carbon emissions by up to 15-30%.

Highly scalable and easy to integrate with new or existing energy utilisation meters, the Energy Manager solution simplifies commissioning and enables rapid return on investment. The software is available either pre-installed on edge hardware such as the PACSystemsTM RXi2-BP industrial PC or as a stand-alone application to be installed in a virtualised environment.

"Reliable and accurate monitoring of energy costs and emissions is becoming invaluable for all organisations," said Eugenio Silva, Intelligent Automation Product Manager of Emerson's Discrete Automation business. "Our new Energy Manager solution gives operators, plant managers and corporate sustainability teams greater visibility and insight into energy consumption and operating costs at any given time. This enables companies to track progress and meet targets, comply with regulations and reliably reduce their impact

environmental impact.

For more extensive monitoring of media and utilities, Energy Manager can be combined with Emerson Compressed Air Manager to provide a simplified view of energy costs and compressed air usage by machines in a production line, plant and site.

Daniele Toni

Daniele Toni