di Carlo GAI

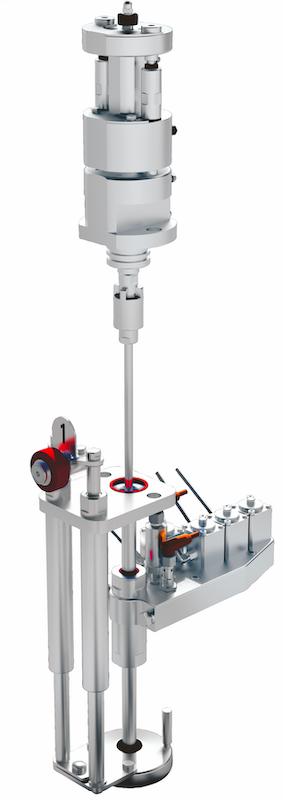

The flagship of GAI machines is the UNICA filling electropneumatic valve. It is a patented solution (2013) that thanks to its particular design and technology, allows a high control in the filling process of each individual bottle, optimizing it.

Today all GAI bottling solutions adopt UNICA which, thanks to a particular attention to oxygen pickup, maintains the characteristics of the wine unchanged, increasing its shelf life.

'Air'is a very sensitive subject when it comes to wine. Too much air means oxidation, resulting in worsening product quality, loss of aromas and color decay. But even the complete absence of air does not suit a living material such as that of wine and can cause unpleasant reductions. Studies have confirmed what millennia of practice have always "known": the exchanges between wine and oxygen,during the elevage in barrels and, later, the aging in the bottle through caps of permeable material, are the basis of a slow evolution of wine, an integral part of its own process of ennoblement and aging.

If at one time the boundary between aging and acidification was entrusted to the expertise of the wine-making, which acted empirically and experimentally, today we know that this boundary is much more controllable. A rational use of oxygen in all stages of vinification helps to preserve the quality of the wine and allows to obtain more valuable products. However, the monitoring of the relationship between wine and air must be scrupulous and continuous: oxygenation or reduction are permanent changes in the material, from which there can be no turning back. Since the technology became permanently part of the cellar processing, all the winemaking phases have been equipped with tools dedicated to air control and its "dosing": automatic vinification plants with integrated macro-oxygenation systems, micro-oxygenation tools during aging, oxygen detectors and highly technological systems for the removal of dissolved excess oxygen in the wine.

Since 2013, Gai has attempted to respond to the problems of oxidation being bottled with an original patent, the UNICA electro-pneumatic filling tap, whose balance sheet is now consolidated and is used for practically all Gai solutions. Compared to traditional mechanical taps, UNICA has four electro-pneumatic valves, each dedicated to a circuit: vacuum creation, tank gas injection, leveling gas and exhaust. A unique feature is the pneumatic management of all valves, which can be controlled by PLC. A digital management that, bypassing the mechanical management in fixed cycles, greatly increases the flexibility of the "super-valve". In practice, UNICA is programmable day by day based on the characteristics of the liquids to be bottled and the specific bottling conditions.

In other words, it is the tyre that, digitally controlled, allows an extremely flexible management, respectful of the raw material and "dedicated" to the product: UNICA can be used for sparkling wines, sparkling wines, still red and white wines, soft drinks and fruit juices. Characteristic of UNICA is the deareation capacity of the oxygen present in the bottle which, once sucked in, is replaced by an inert gas. The result is a drastic reduction in oxygen pick-up and the guarantee of a product that, once closed and packaged, will not only last longer, but will keep its organoleptic characteristics unchanged. Thanks to UNICA,all the production efforts used in the vineyard and in the cellar to obtain a product of excellence are preserved and enhanced even during bottling. Winemakers, technicians can forget about the concerns related to bottling oxidation and focus on what healthy do best: wine.

A single tap, a thousand advantages

UNICA is anelectro-pneumatic "super valve" that, in addition to preserving wine from oxidation, performs equally important tasks. The filling offered is highly flexible, with the possibility of working at atmospheric pressure, light pressure or high pressure, simply setting the working pressure from the control panel: a precaution that allows you to bottle all types of products in an ideal way, from sparkling wines to still liquids. Format changes are also very simple because they can be stored digitally and recalled automatically, without the intervention of a specialized technician. The level adjustment is automatic and centralized, with an adjustment range from 25 to 100 mm from mouth satin, and can be modified while the machine is in operation. UNICA allows to obtain precise levels even without leveling, thanks to the closure of the filling channel and the gas return channel near the bottle level. In addition, it greatly improves the degassing phase, as it eliminates the disturbance caused by the degassing of the product contained in the gas return channel, gaining considerable productivity on sparkling products. UNICA is delicate and precise as it is reliable. The filling cycle, managed with timed phases, guarantees maximum repeatability of operation, making it in fact insensitive to changes in speed on the production line: timed management allows to optimize the work phases, generating an increase in production volumes.

UNICA is anelectro-pneumatic "super valve" that, in addition to preserving wine from oxidation, performs equally important tasks. The filling offered is highly flexible, with the possibility of working at atmospheric pressure, light pressure or high pressure, simply setting the working pressure from the control panel: a precaution that allows you to bottle all types of products in an ideal way, from sparkling wines to still liquids. Format changes are also very simple because they can be stored digitally and recalled automatically, without the intervention of a specialized technician. The level adjustment is automatic and centralized, with an adjustment range from 25 to 100 mm from mouth satin, and can be modified while the machine is in operation. UNICA allows to obtain precise levels even without leveling, thanks to the closure of the filling channel and the gas return channel near the bottle level. In addition, it greatly improves the degassing phase, as it eliminates the disturbance caused by the degassing of the product contained in the gas return channel, gaining considerable productivity on sparkling products. UNICA is delicate and precise as it is reliable. The filling cycle, managed with timed phases, guarantees maximum repeatability of operation, making it in fact insensitive to changes in speed on the production line: timed management allows to optimize the work phases, generating an increase in production volumes.

The proximity sensor built on board each tap, in addition to ensuring the real presence of the bottle, allows you to start the filling cycle at the exact moment when the bottle makes the seal on the cone, without waiting for the lifting piston to complete the maximum stroke as is the case in in traditional pressure fillers.

Finally, a pressure translator allows you to immediately check the pressure in the bottle in order to verify the correct progress of the filling cycle and to detect any anomalies or malfunctions: unscrew the tip seals, insufficient vacuum degree, exploded or defective bottle.

UNICA'S Pluses

- From choppy wine to uncompromising still wine

- Increase in yield to 30% more for choppy wines

- Level adjustment from 25 to 100 mm from mouth satin, automatic and centralized without any manual intervention. It can also be carried out with a machine at work.

- Totally repeatable fill cycle, possibility to store the correct working sequence. All phases maintain the correct durability even by changing speed.

- Optimized sterilization by opening and washing one circuit at a time, always with the pressure and time necessary for each circuit, in a totally automatic way.

- False automatic bottles (for machines with 20 or more taps, and manuals for 12 and 16 taps). They are always present on board the car.

Four valves "in one"

As already mentioned, UNICA is a tap that uses four electro-pneumatic valves, each dedicated to a specific function: vacuum creation, tank gas injection, leveling gas and exhaust. Compared to traditional three-valve taps, the novelty is the tank gas valve, that is, the one that allows you to make the pressure compensation in the bottle without using the gas return channel. Thanks to this precaution it is avoided to spray product residues inside the bottle and, above all, it is avoided to consume "new" gas with each bottle. All four "valvoline" are made internally by Gai and are tested one by one before being mounted. Capable of working up to 8 bar of pressure, they are controlled by bus and connected to the company PLC: a peculiarity that allows an immediate response, in the order of hundredths of a second.

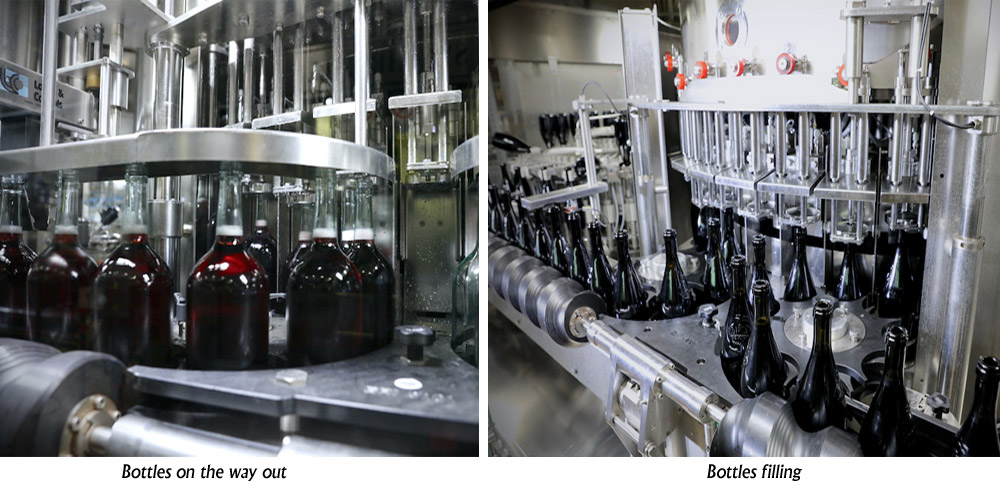

Bottling, the most critical moment

While it is true that winemaking has given due importance to the "amount of air" in contact with wine, bottling has always been the most critical moment: a little out of ignorance, a little through negligence, a little for the objective lack of solutions dedicated to this problem. For a long time it was believed that, once ready, the wine could be bottled without problems, neglecting or minimizing contact with air during the phases of passage from the tanks to the glass. As a result,

wine design also did not pay sufficient attention to the risks of bottling oxygenation, developing machinery and technologies that avoided the problem in the face of a considerable increase in volumes and a substantial reduction in packaging time. Although one may think that all this is obvious, it is not.

In 2017 an important conference of Assoenologi dedicated to oxide reduction of wines reiterated the importance of bottling as a fundamental phase to increase the shelf life of a wine, or its "life on the shelf". As pointed out by experts, during bottling, on average, up to 3 mg of oxygen are introduced but, controlling and improving bottling conditions, each reduction of 1 mg corresponds to saving one year of oxidation.

UNICA is the electro-pneumatic tap that, working on pneumatics, deaeration and insufflaggio, enhances the work of wine producers.. While it is true that bottling technologies cannot improve the product they package, it is also true that, when they are designed sufficiently, they can make it worse, and by a lot. Gai has dedicated years of research to the fight against bottling oxidation and to the flexibility of the tyre so that the speed and efficiency of the solutions will never lack respect for the raw material: good table products are also born from good air.

Daniele Toni

Daniele Toni