From complete PET processing lines to new solutions for the chocolate industry (with an eye to bakery products), the complete SACMI range for the beverage and food sector will be taking centre-stage at IPACK IMA 2018

Integrated bottling solutions

The world’s only player with a technology portfolio capable of handling every stage of bevarge production, from packaging (prefotrm-closure-labels) to finished product, SACMI will soon be presenting all its latest at the international Ipack Ima fair (FieraMilano, 29 May- 1 June 2018).

Lightweight and integration are the keywords for solutions covering every stage in the process, from the preform and closure through to the filled, capped and labelled bottle.

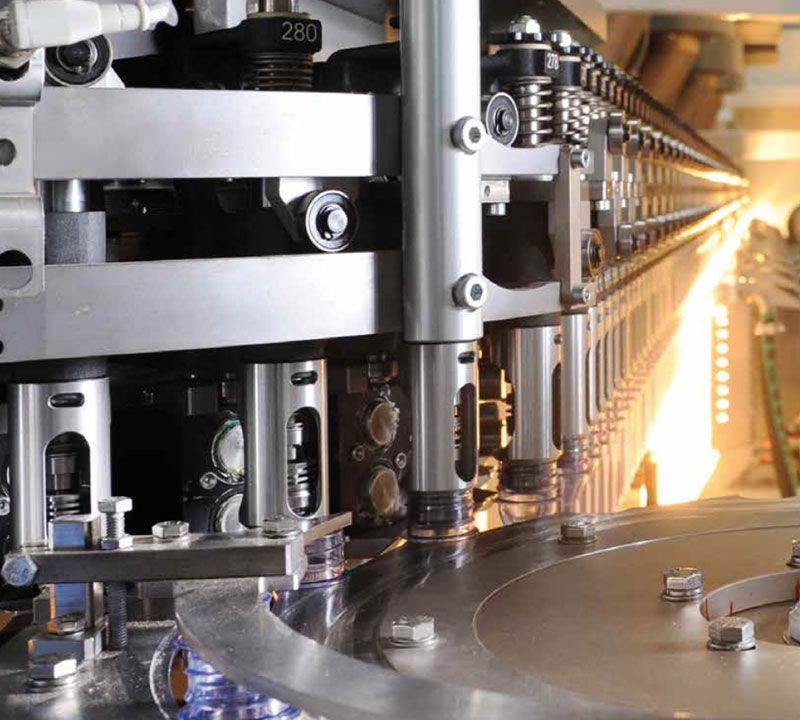

CCM - Continuous Compression Moulding

One of SACMI’s new offerings for the global closures industry is CCM (Continuous Compression Moulding) technology, a solution that offers numerous advantages for customers. These include extremely low operating costs, low cycle times, high productivity and reduced weight, as well as the ability to control each individual mould cavity, set the parameters directly from the operator interface and verify output quality in real time.

Lightweight and high performance closures and bottle necks

But although a high technological level is an essential factor, it is not sufficient on its own. A key aspect for SACMI is the ability to design the entire closure-bottle system together with the customer and to provide all the technologies necessary to perform the entire process from the pellet through to the finished product. The capacity for integrated design of the closure-preform system has enabled Sacmi to develop increasingly lightweight and high performance closures and bottle necks, experimenting with new market standards and exploring the latest frontier of a sector that is increasingly attentive to quality and sustainability of production.

HEROline

The culmination of years of research and expertise in the sector is the new HEROline, an integrated solution that begins with the production of the preform and the closure (two processes that are now synchronised thanks to the SACMI CPB Link magazine) and continues downstream with stretch-blow moulding, filling and labelling.

The culmination of years of research and expertise in the sector is the new HEROline, an integrated solution that begins with the production of the preform and the closure (two processes that are now synchronised thanks to the SACMI CPB Link magazine) and continues downstream with stretch-blow moulding, filling and labelling.

Available on request complete with the innovative HEROblock system (the “all-in-one” unit combining stretch-blow moulding, filling, closing and labelling), HEROline reduces handling operations and increases logistic efficiency, reduces energy and raw materials consumption and ensures an extremely high level of versatility in product management and development.

In short, it offers a practical response to the challenges posed by today’s beverage packaging industry in the light of Industry 4.0 criteria.

Added to this is the possibility of real-time monitoring of production and machine operation parameters by means of the Sacmi H.E.R.E. (Human Expertise for Reactive Engineering) supervisor and innovative customer support services (Sacmi Total Care). But the scope for customisation goes much further than this. For example, each individual closure can be coloured and decorated with a pre-chosen logo (COLORA CAP), while the label can be printed digitally and applied to the filled and capped container (D-Match), even in the case of small batches and exclusive production runs.

Such SACMI connecting technologies completely revamp the way we look at production and service and are, in fact, already a reality that visitors to the IPACK-IMA fair will be able to see for themselves at the Group's stand

Daniele Toni

Daniele Toni