Balluff at Ipack IMA - Hall 5 Stand A 45

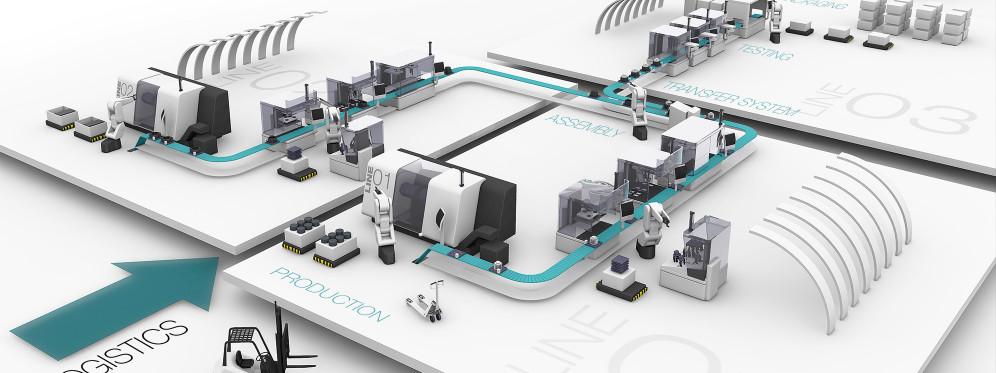

Balluff is the ideal solution for anyone interested in fast format changes using high precision movements with measurement and position systems, as well as the guarantee of quality and reliability up to the so-called "lot1" which characterizes maximum production flexibility. It will be precisely shown how the flexibility of the machine can be considerably increased through the fast and reliable recognition of the interchangeable parts using RFID or vision systems.

We will also talk about how the use of IO-Link helps to simplify the installation of a system, lower setup and order times, reduce costs and how intelligent diagnostics and parameterization can be implemented quickly and with excellent cost / effectiveness ratio. With the new communication standard the concepts of intelligent modularization can be easily implemented thanks to plug-and-play. IO-Link is considered enabling for Industry 4.0.

Another important issue is that of level control. Balluff is the first company on the market to offer self-adhesive capacitive sensors in IP 67 protection class for continuous level control and in the absence of contact on non-conductive containers or external walls of glass, plastic or ceramic pipes. The flexible sensor head, with a monitoring range up to a length of 850mm, can be cut independently on site to the desired length (minimum 108mm) and easily attached to tank walls by means of the integrated adhesive surface, without the need for additional accessories.

A further innovation is represented by the I / O modules with 8 IO-Link ports and IO-Link nodes with "DaisyChain" extension port. These are part of the new family of IP67 I / O distribution modules for extreme conditions in the Food / Beverage and Pharma machine market. Corrosion resistant and detergent and stainless steel modules offer an easy-to-clean design and are certified by Colab. They ensure reliable and error-proof signal transmission even in harsh environments and at high data rates.

Reliable traceability of all data through the high performance of RFID: another important topic at this fair.

Balluff sensors from the extensive portfolio of high-pressure and Ecolab-certified products for the hygiene industry offer everything to make the packaging process safe, stable and hygienic. The materials of the enclosures, safe for foodstuffs and resistant to aggressive cleaning agents, make them the number one choice for processes in humid environments that require high hygiene typical of the food industry. Thanks to the IP67, IP68 and IP69K certifications, as well as the resistance to temperatures up to 120 °, the great seal guarantees the best quality for a long product life and for the reliability of the process.

Daniele Toni

Daniele Toni