OMAG packaging solutions on display at Ipack-Ima

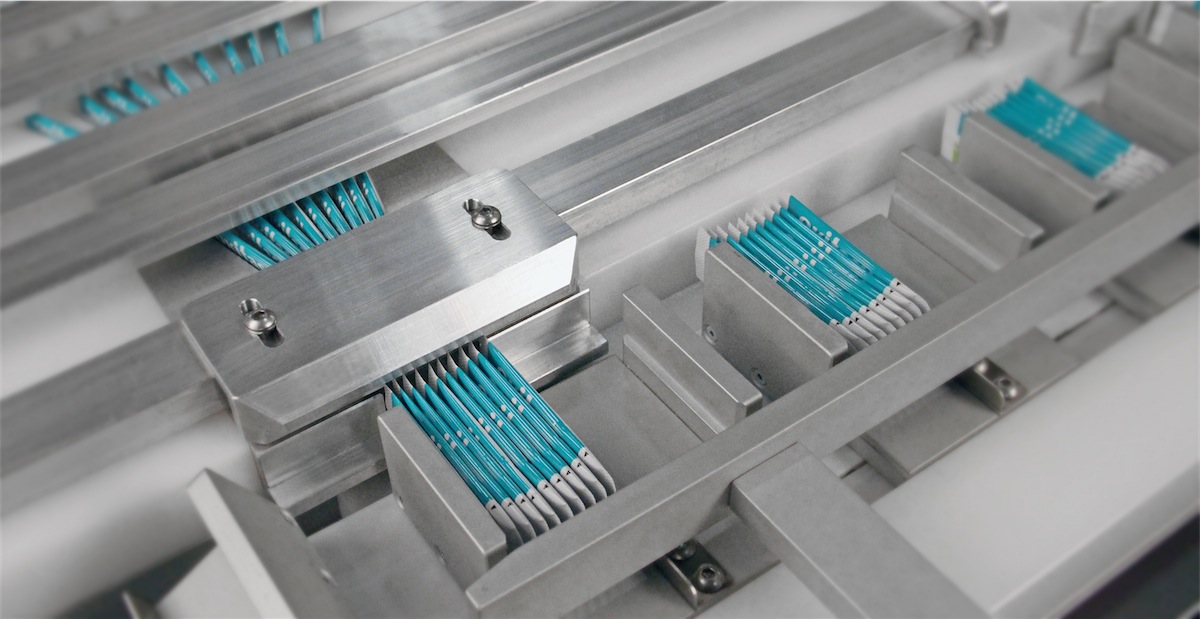

After a careful technical research and continuous investments in research and development, Omag will present an absolute preview at Ipack-Ima the C3i vertical model intermittent motion packaging machine, technology and accuracy of the stick machines applied to the packaging in envelopes welded on 4 sides .

It will also be possible to observe closely the CS /10 intermittent movements packaging machine for the packaging of granular and sliding stick-pack products and the CS-Junior, designed to handle sensitive and packaged products in small batches.

Omag is waiting for you at Ipack-Ima to show you solutions dedicated to the food sector. Hall 5 - Stand B38

Omag, over 40 years of experience in food packaging

Since 1973 Omag has designed customized solutions based on the customer's production needs.

Omag srl deals with the design and construction of machinery for the packaging of dusty, granular food or pharmaceutical-nutritional products (sugar, coffee, tea, spices, yeast, etc.) and liquids (ketchup, mayonnaise, oil and single-dose vinegar, etc.) intended for restaurants, bars, canteens or large retailers.

The production includes a wide range of vertical and horizontal packaging machines, with continuous and intermittent movements for the packaging of granular, dusty, liquid and pasty products in heat-sealed bags on all 4 sides, stick-pack, Doy-pack or Stand-up.

Each packaging machine can be designed on a variable number of rows, equipped with different metering systems, combined with robotic counting systems, cartoning machines and casepackers, completed with several optionals - markers for printing lot and expiry numbers, scales, etc.

The series of machines designed by Omag srl are particularly suitable for satisfying the needs of the food industry (meat, frozen food, fish products, cheese, chocolate, etc.) and an electronic control system is in place on the whole range of machines. immediate and extremely precise verification of the food packaging process and of the various operations in progress (machine status, number of packages produced, regulation of the temperature and speed of the packaging, verification of energy consumption, etc.).

Daniele Toni

Daniele Toni