Discover the new generation of labeling machines, increase the efficiency of your production

The systems Espera Nova are born for the new digital world INDUSTRY 4.0 and are distinguished by the new simple and intuitive software, the connectivity, the large 21 "touch display, with the swipe-monitor features that make the use simple and intuitive, as your smartphone.

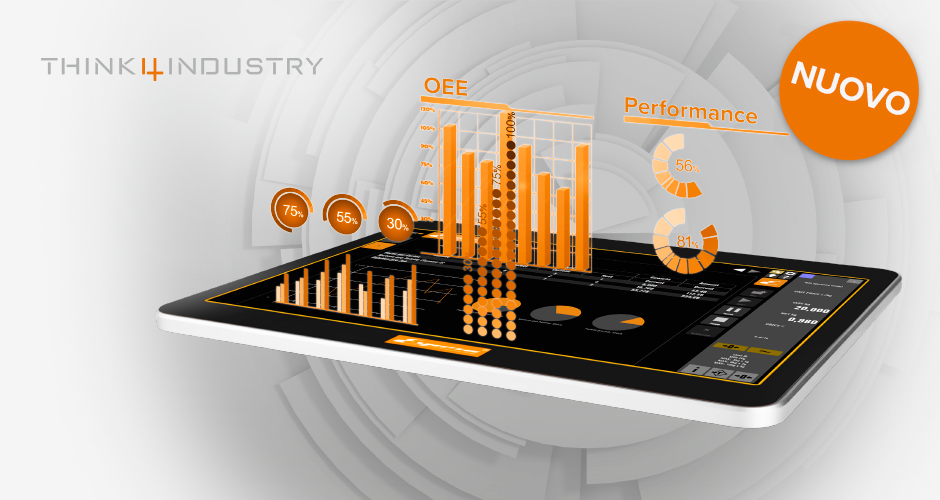

Espera Nova adapts to your production process, and not vice versa, thanks to the new Think4Industry software, simple and intuitive, but also thanks to the automatic positioning of printers and guides. In conjunction with the 3D Camera, automatic adjustments are defined for each product during the labeling process.

Fast change roll labels; this technology alone saves time and money during daily production.

Protect +: maximum protection from water splashes, thanks to the IPX5 system and a clean and linear machine design. Thanks to these features and to the open and spacious design, it is easy to clean and maintain, without tools.

Anywiew: control and intervention on the entire production process even on the move, for example via smart-phone or tablet. it is configured as a web server, allowing remote access and control, while still guaranteeing the security of your data.

AnyView allows you, together with Think4Industry software, to perform a real predictive maintenance, indicating the life of the parts, the remaining life, also indicating the frequency of maintenance operations. In the event of an error or failure, the system displays and indicates the faulty part, suggesting the necessary recovery operations, the required spare parts and, if desired, activating a Service Call directly to the service center.

3D Camera: the innovative 3D camera captures the shape of the package in real time, during the production process and automatically stores the shapes of the packages in the database and identifies independently where it is better to place the label on each package.

Particularly recommended for irregular products such as whole chickens, flow-pack vegetables, vacuum or cheese cuts.

The system is characterized by extreme flexibility and modularity, both hardware and software, and allows an easy adaptation to the various operational needs. In particular, the printing groups can be inserted either from above or from below, in a flexible and configurable way. All the printing groups, if alternated, allow to change the label roll without stopping the production process.

The innovative thermal head control system allows to monitor and manage every single printing DOT, verifying the efficiency, the remaining life and allowing a specific overdrive, on the single point, to increase the working life. The software also allows, in case of damaged DOTs, a simple movement of sensitive data.

Switch & Go: the innovative modular application systems, starting from the classic and appreciated applicator piston with label rotation during application (360 °) have evolved, adding the new oscillatingpiston which, following the product in motion with a 'controlled oscillation’ and in conjunction with the 3D camera, allows a fast, reliable and precise application, maintaining the rotation capacity and automatic height compensation; particularly suitable for high speed requirements.

Added to this is the new air application system which, by approaching the label to the product thanks to the piston, shoots the label on the product in the last section: this allows, while avoiding contact, to have a high precision and reliability of application. Maintains the ability to rotate the label and automatically compensate for height; particularly suitable for high speed needs with delicate product.

Linear contact piston which, together with the 3D camera, allows a fast, reliable and precise application, maintaining the rotation capacity and automatic height compensation; particularly suitable for medium speed requirements.

The original application system from below, designed to deliver the label in the space between two conveyor belts, without the need for passage openings and complex adjustments, allows an application from below precise and effective, without any need for support systems product.

The New Label Designer, together with the Barcode Designer and the simple management of the fonts (freely loadable on the system), allows a simple design and maintenance of your labels. The ability to load the layout of your labels, allows you to design directly on the real label, which you can see AS IS at any time of design and production.

These absolutely innovative features will allow you to see the production and logistics process with new parameters and opportunities, in search of the best efficiency and profitability of the labeling processes. The new Think4Industry software and the connection capability introduced by AnyView, even on the move, will revolutionize your point of view and the approach to the labeling processes.

The digital revolution Industry 4.0, has allowed ESPERA to further deepen its vocation for the efficiency of technological processes, creating new printing systems, applications and new software that will revolutionize the traditional approach to labeling.

Daniele Toni

Daniele Toni