Omac is market leader in production of lobe pumps, is pleased to present a new range of sanitary-hygienic pimps to satisfy the high standard required for food and pharmaceutical industry applications.

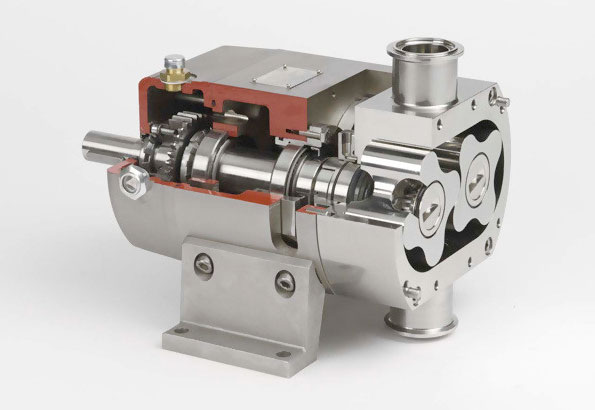

New series “C” pumps

The new series “C” pumps incorporate a new front loading seals design which enables easier and quick service. Maintenance is also improved by a new external axial adjustment system and new single taper roller bearings.

Designed to achieve the highest hygienic standards, they can be easily cleaned in order to reduce hot water consumption and chemicals for CIP operations, EHEDG'S certification (European Hygienic Engineering & Design Group) has already obtained.

Used material, surface finish as well as design requirements are developed to obtain also 3A Sanitary Standard certification. All wetted parts are in stainless steel 1.4404 or 1.4435. The pump body is casted or press-forged and has integral non welded connections.

The rotors have been designed to achieve the best efficiency combined with minimal product damage. C range pumps enable further energy-saving , a lower absorbed power got by reducing the internal frictions and improved efficiency thanks to the possibility of selecting three different rotor clearances according the working pressure. Initially are expected two types of rotor, four-lobe and new dual wing design.

New design also for compact and strong gear case in Nickel plated cast iron or 304 stainless steel with rounded profile and feet for horizontal and vertical installation (self draining position). “C” range will be suitable for working pressure up to 15 bar with standard clearances rotors. New C series lobe pumps with easy maintenance, high efficiency, robustness, reliability and potential for handling corrosive, abrasive and aggressive chemicals are particularly attractive.

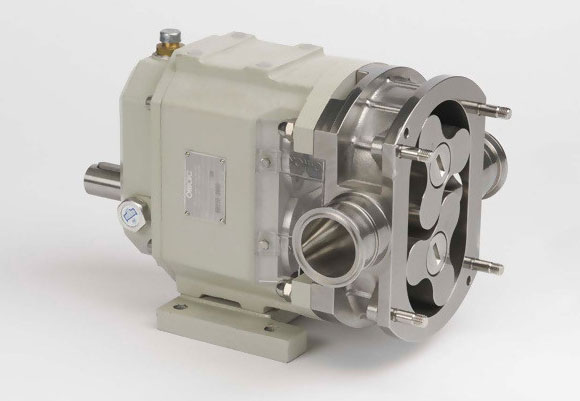

BB/BA series

BB/BA series conventional lobe pumps in AISI 316 stainless steel are assembled on a cast iron gear box which has a protective coating in epoxy paint finish or Nickel plated as option. The structure is conceived in the respect of the rigorous American Sanitary Standard 3A (new standard Number 02-10, Auth. No. 810) and assures good services, long endurance, easy and cheap maintenance. The chamber separating the rotor case and gear box enables the fitting of balanced compact reversible mechanical seals, avoiding the contamination between the pumped fluid and the gearbox lubricant. The base of the gearbox is designed to make installation easier for connecting into horizontal and vertical pipelines.

This range consists of 17 models with deliveries from 0.05 to 200 m³/hr with the following versions available: ST Model with standard tolerances, SM Model with increased tolerances, both being made in AISI 316 stainless steel and both available with Duplex shafts. HP Model has crescent shaped rotors in anti-seizure stainless steel alloy with shafts in Duplex for counter pressures up to 20 Bar. The OMAC Lobe Pump is modular in design allowing the main parts such as the rotor and seals, to be changed quickly and easily. A wide range of rotors, seals and gaskets is also available.

Developed from the successful existing range of OMAC “B” series pumps, the series “BB-BA” pumps retain the principles of performance, solidity and reliability and incorporate a new design which enables easier cleaning of the wetted parts. BA series has obtained 3A Sanitary StandaRD certification.

Daniele Toni

Daniele Toni