The linear monobloc MLE4441 CAN is a high-tech great solution for craft brewers aiming to sell canned beers too. This container is easier and safer to convey and reduces ageing, as it protects beer from the sunlight integrally. An infeed screw introduces cans into the monobloc and moves them below every station with perfect synchronism.

RINSER

Cans are grasped from the external top rim by a pincer and turned upside down through a chain system with step-step motor. The nozzle enters the can for 15mm. The two injection circuits (water and air) are completely separated. The durations of injections are adjustable through control panel and the operation occurs only when the can is present. The dripping liquid is collected in a close circuit without wetting the machine. The air injection substantially reduces the water residue into the can.

FILLER

Cans are moved to the filler where pneumatic pedestals lift them towards the filling valves. The following operations are performed in sequence: • can presence detection (if absent, the filling cycle does not start); • gas injection, which replaces the air in the can with inert gas to reduce oxygen presence; • filling • levelling (if required); • degassing. A transducer constantly checks the can internal pressure (the valve does not perform the filling operation if the can does not reach the tank pressure). The filling level is centralized and can be adjusted manually. The valve can fill sparkling and still liquids with pressure between 0 and 4 bar. The filling level is precise even without the levelling operation. The valve is then completely closed and this improves the degassing even with particularly difficult products. The functioning pressures are set from the control panel and handled by PLC. The filling valve is under patent protection.

CAN LIDS DISPENSER

Four lids are singularly released from the loader and dropped on a sideshifter, which moves them above the cans. Then, the inert gas injection and water jet for beer foaming are performed. The gripping devices hold the lids and lay them on the cans with a light pressure when the sideshifter withdraws. The gas injection and the water jet circuits are completely separated. Those operations are performed only when the can is present and the duration is set on the control panel and handled by PLC. The neutral gas injection and the water jet for beer foaming substantially reduce the oxygen quantity in the space between liquid and lid.

SEAMER

The intermittent star moves the can on the lifting plate, which lifts it and brings it next to the rotating spindle. While the can turns, the two rolls seams it. All operations are controlled by mechanical cams.

WEIGHT CONTROL

After the seaming, the can is moved on a load cell to check the weight: if it is less or more than the pre-set values, the can is then removed through the expeller included in the supply.

WASHING TUNNEL

Outside the monobloc there is a washing tunnel for cans.

On the same structure,there are four can lid storing columns/ loaders to supply the distributor.The lids can be easily introducedinto the four loaders while the monobloc is running.The loaders shift is improved by a quick coupling. Themonobloc can be provided with a cleaning and sanitization CIP system.

The rinser, the filler and the gasnjection/water jet units are provided with manual dummy bottles for a correct washing cycle.

UNICA THE NEW FILLING VALVE

UNICA THE NEW FILLING VALVE

The satisfaction of our customers confirms the success of the electropneumatic valve UNICA, patented inthe whole world (N° 1413689-1417119 and extensions).. The valve features are: From 0 to 8 bar workingpressure; 25 to 100 mm filling level from the rim; Approximately 0.5 mm filling precision; Extremely lowoxidation; Easy and complete sterilization.

The filling valve is suitable for an extensive range of products, such as sparkling wines, still wines, high quality beers and other beverages that require extreme care in

terms of oxidation, foam formation and sterilization.

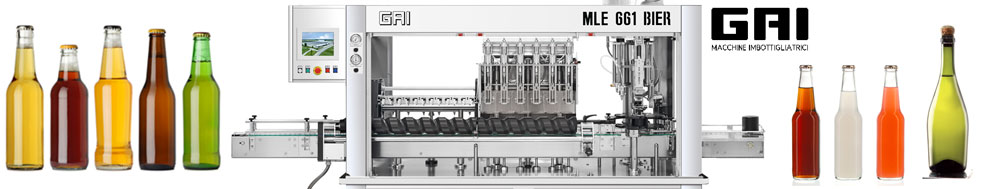

GAI COMPANY

Gai company, grounded in 1946 by Mr. Giacomo GAI, is leader manufacturer in the bottling machines Worth-known product is the “monobloc”, enabling the whole production process in just two machines, one for the phases from rinsing to capping, and the other one for the labelling.

The target sectors are the ones referred to wine, oil, distillates and, increasingly, BEER.

Cornerstones of GAI have remained unchanged through time: technical assistance and spare parts guaranteed for lifetime; 70% of the energy needs from renewable sources; investment in technology and in trained human capital. Up to obtain also the ISO 14001 certification, a high prestigious achievement.

Today the seat of Ceresole d’Alba, surrounded by greenery in Piedmont countryside, reaches 170.000 quadrat/meters, 14.000 m² covered by photovoltaic panels, with production of 1.800 KW of electric energy. 200 employees. These numbers talk about a company well established over the years, ready to meet the challenges for the future.

Daniele Toni

Daniele Toni