For over 80 years, FAVA SPA has been a protagonist in the production of industrial plants for pasta factories and has always been identified as a reference company.

Thanks to the patented technologies, developed and refined, every raw material is fully enhanced, always obtaining a product of the highest quality with optimized drying diagrams.

The flexibility and simplicity of plant management has always been the strength of the Company, which devotes great attention to over 2000 customers worldwide, with dedicated after-sales assistance, training courses and a research and development laboratory for the study and improvement of ever-effective technologies.

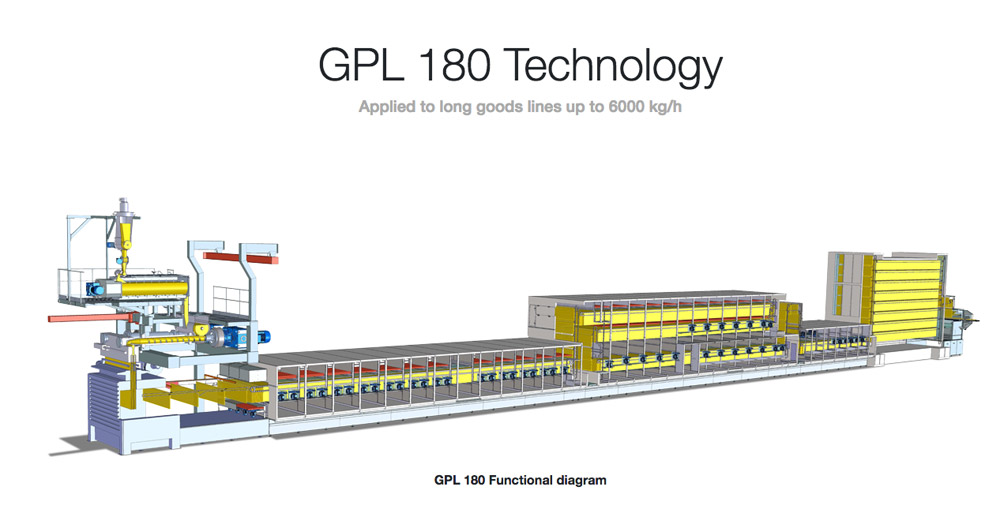

The LPG 180 long pasta drying line is the most advanced drying solution on the market today.

Drying times have been reduced by the latest patented FAVA SpA technology to 180 minutes, which is about 50% of the drying time of standard dryers.

This technology allows to obtain finished products identical or even of higher quality than products obtained with traditional technologies, but without damaging the product in the preliminary and main drying phases, which are similar in principle to the classic installations of the TCM Eco -system line produced by FAVA SpA. The technology allows to obtain a better and clearer color of the pasta while maintaining a productivity, comparable in quality, if not better, produced in cooking, resistant to mechanical stresses and at the same time very flexible, which means easy packaging.

This technology allows to obtain finished products identical or even of higher quality than products obtained with traditional technologies, but without damaging the product in the preliminary and main drying phases, which are similar in principle to the classic installations of the TCM Eco -system line produced by FAVA SpA. The technology allows to obtain a better and clearer color of the pasta while maintaining a productivity, comparable in quality, if not better, produced in cooking, resistant to mechanical stresses and at the same time very flexible, which means easy packaging.

The equipment is designed using a 3D CAD system in compliance with two main criteria: rationality and modularity.

All the component parts of the machine are designed and brought to construction perfection, fully ready for functional use. Reducing the equipment set facilitates the maintenance of the pasta factory.

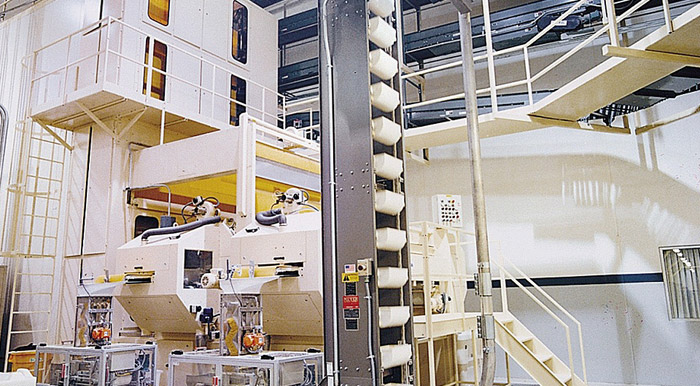

T he kinematic movement of chain-system bastuns is an absolute novelty for this sector. It provides independent operation of motors located in different environments, a classic feature of FAVA SpA production lines, the basis for technological adjustments during transitions or emergency situations. At the same time, it ensures continuous operation through adaptive motion adjustment based on a simple and reliable mechanical system that limits stresses on the mechanical parts of the equipment.

he kinematic movement of chain-system bastuns is an absolute novelty for this sector. It provides independent operation of motors located in different environments, a classic feature of FAVA SpA production lines, the basis for technological adjustments during transitions or emergency situations. At the same time, it ensures continuous operation through adaptive motion adjustment based on a simple and reliable mechanical system that limits stresses on the mechanical parts of the equipment.

Due to its small size and lack of steam, the equipment consumes less energy resources than traditional technology. The line is equipped with a very powerful cooler with side ventilation system for the preparation of pasta for the following stages of production: packaging or storage in bins. The modern control system through control devices is a simple and intuitive system to use that guarantees the normal and safe operation of the line at all stages of the production cycle.

The design of this line has been developed to meet the needs aimed at increasing the efficiency of production in extremely small spaces of length, while optimally exploiting its height.

ADVANTAGES

- Innovative drying technology (patented)

- Mixer "Cyclone"

- PREMIX system ®

- Beltmix ® system (stabilization tape) or EMPTY FULL ® - ® technology

- Compression screws

- Advanced design

- Adaptive chain transmission system for driving bastuns (patented)

- Saving thermal energy

- Reduced service times

- Reduced line uptime

- logistics

- Easy-to-use state-of-the-art control system

Daniele Toni

Daniele Toni