Nitrogen Generator NIMOS

.png) The new Nimos generatos can be seen as an evolution of traditional systems using the PSA principle (Pressure Swing Adsorption) which allows a constant production of Nitrogen from compressed air.

The new Nimos generatos can be seen as an evolution of traditional systems using the PSA principle (Pressure Swing Adsorption) which allows a constant production of Nitrogen from compressed air.

NIMOS generators are made of two or more modules with two columns. Each one is filled with high quality molecular sieves, characterized by a high porosity and therefore by an excellent selectivity.

The compressed air, which has been dried and filtered, will pass through one of the two columns ceding other gasses and water vapor to the oxygen sieves. After few seconds, before the sieves are completely saturated, the column will be depressurized in order to release the oxygen into the atmosphere.

At the same time, compressed air will be deflected to the other column, yielding oxygen until the next change.

The cycle, uninterrupted until reaching the filling of the tank, ensures a continuous nitrogen flow. When the tank reaches its maximum filling pressure, the generator, automatically, turns itself off, in standby mode, waiting for a new gas demand.

Oxygen molecules are very small (0,28 mm), and often remain trapped in the cavities characterizing the surface of molecular sieves.

Nitrogen molecules instead, are larger (0,32 mm), and are not captured by the sieve's prorosity.

Food & beverages industry

Main applications:

- MAP Packaging for meats, cheeses, baked goods, fresh pasta, IV Range products

- Sparging, blanketing, bottling of wine and oil, liquid ingredients, grains and powders

.png) Nitrogen in Oenology

Nitrogen in Oenology

A SHIELD AGAINST OXIDATION

In winemaking, the technique of inert wine storage tanks rapidly spread, in order to reduce the amount of oxygen in contact with the product, by injecting gaseous nitrogen. Nitrogen is mostly used in winemaking to prevent wine oxidising, which is a cause of a deterioration of quality, involving changes in colour, aroma and flavour.

THE IMPORTANCE AND ADVANTAGE OF HAVING AVAILABLE ON-SITE generated nitrogen

In cellars, the approach to the use of on-site produced nitrogen happened gradually, to satisfy the increasing demand from innovations with gas injection at bottling. World-wide there is rapid movement towards nitrogen generators replacing the traditional nitrogen production systems, such as bottles or liquid gas, due to the advantages derived from the convenience and cheapness of this system. The key of the success of the nitrogen generator is that by simply switching on the machine, all nitrogen needed can be produced on site, in complete safety, at the desired purity and definitely at lower cost compared to other supply systems.

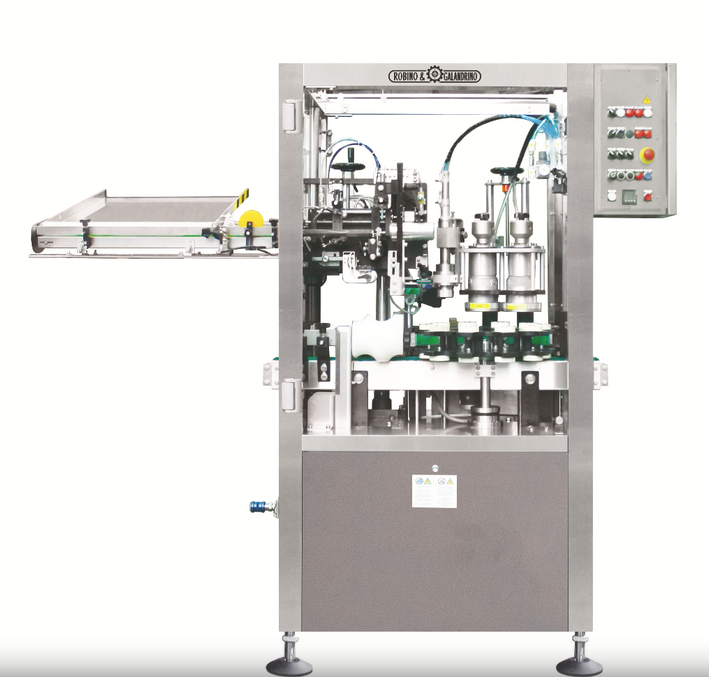

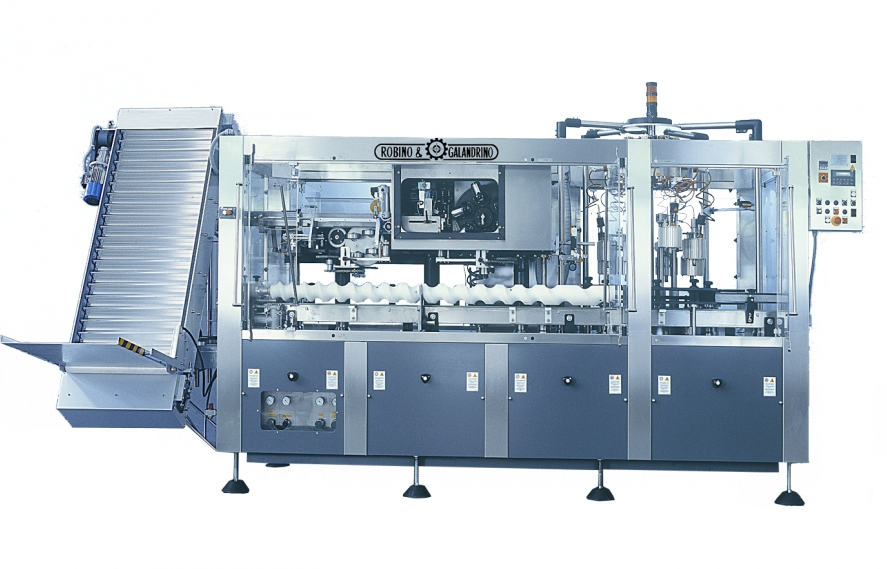

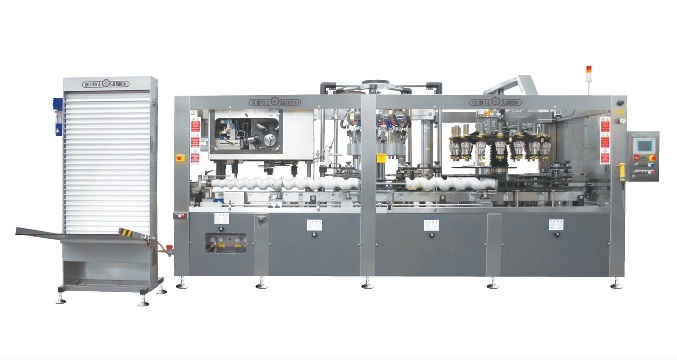

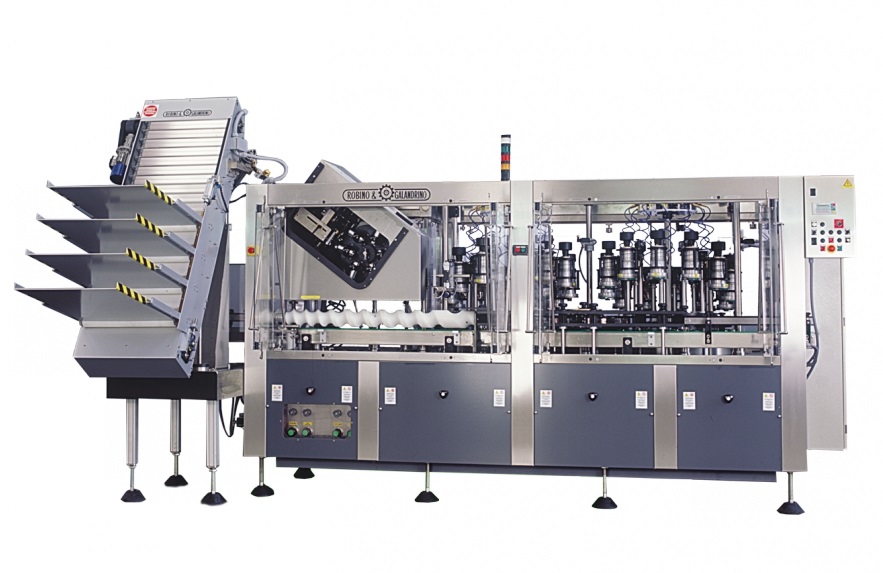

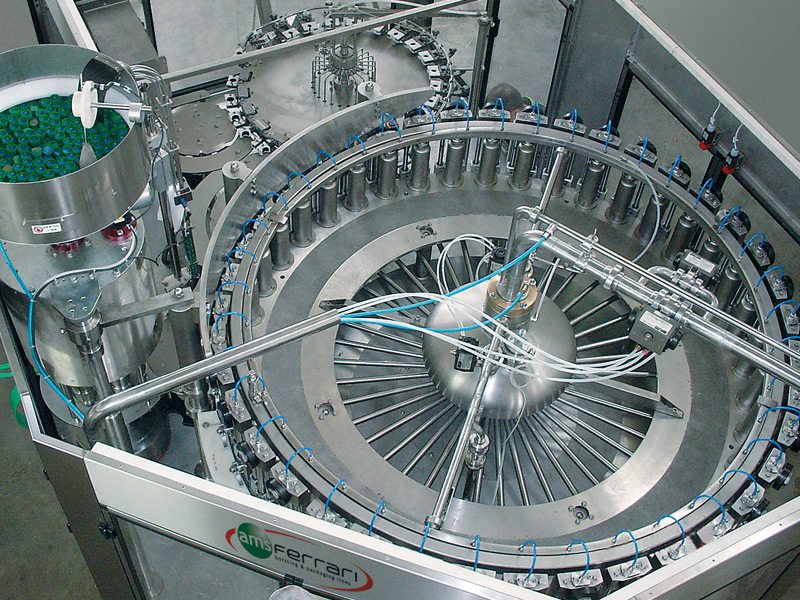

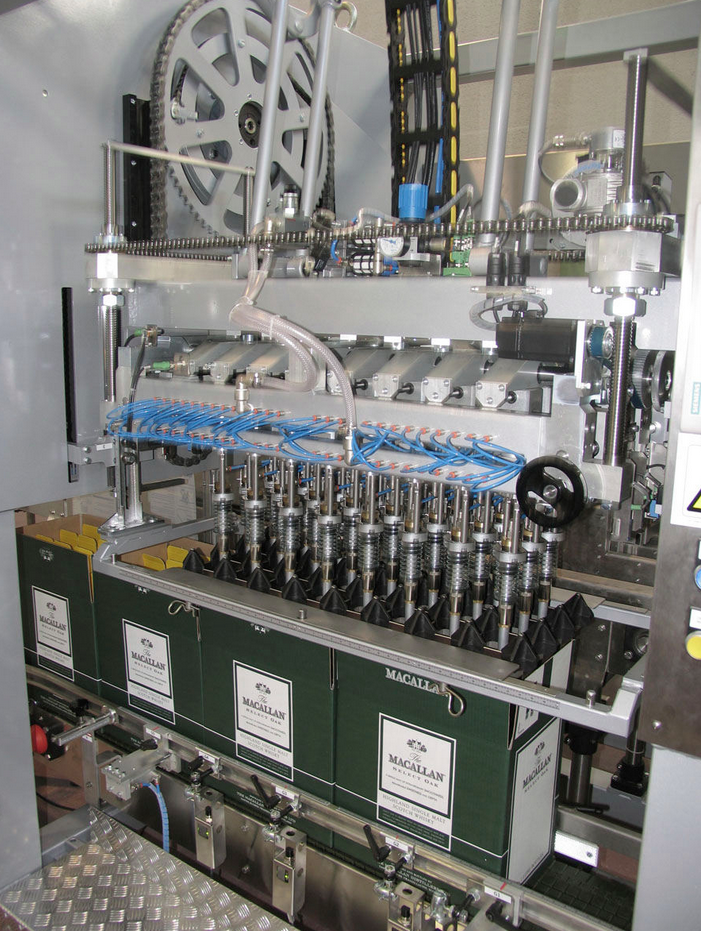

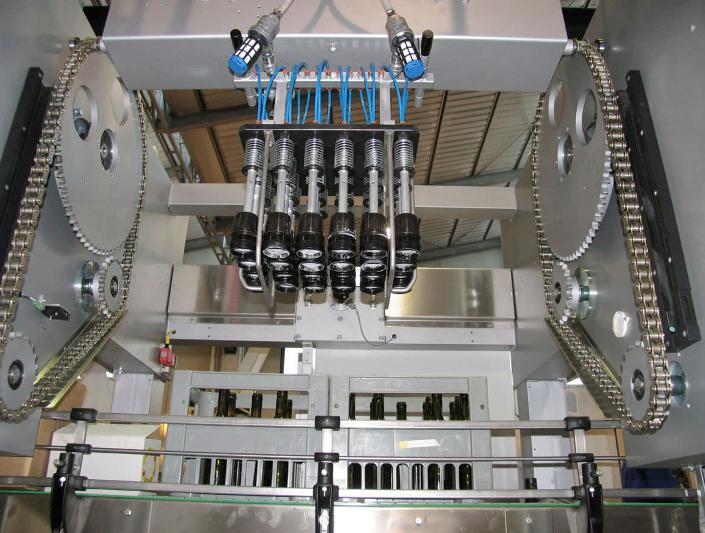

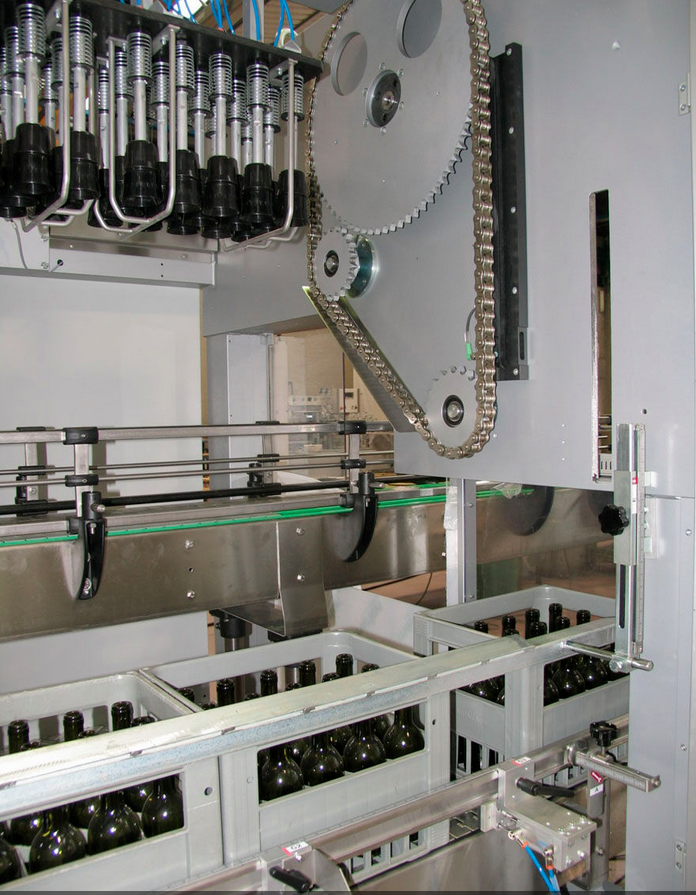

Nortan s.r.l. is a leading worldwide company in the production of capsuling and wirehooding machines for bottling lines, machines for sleeves and food automation. The company has achieved this position from thirty years of research and technological solutions applied in a reliable and flexible way to meet the needs of our customers.

Nortan s.r.l. is a leading worldwide company in the production of capsuling and wirehooding machines for bottling lines, machines for sleeves and food automation. The company has achieved this position from thirty years of research and technological solutions applied in a reliable and flexible way to meet the needs of our customers.

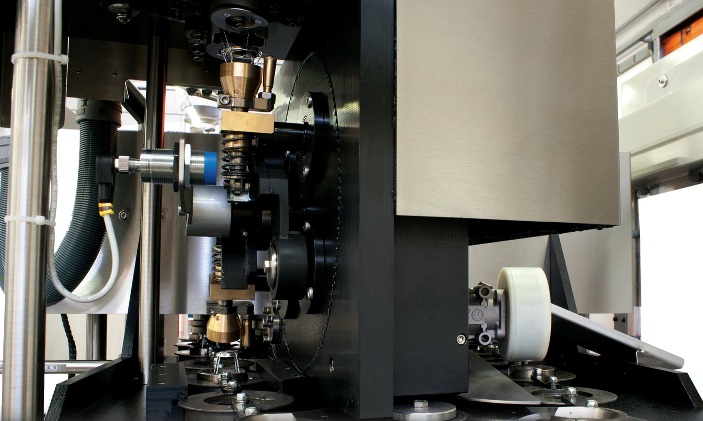

The BBZP, is a single seat valve made with top quality raw materials. Thanks to its versatility, sturdiness and reduced number of seals in contact with the product, it can be installed in all applications requiring maximum reliability in cutting off and directing a fluid.

The BBZP, is a single seat valve made with top quality raw materials. Thanks to its versatility, sturdiness and reduced number of seals in contact with the product, it can be installed in all applications requiring maximum reliability in cutting off and directing a fluid.

The VVF is a manual butterfly valve which cuts off and monitors fluids in the process flow by movements of opening and closing. Characterized by a simple and elegant design and engineered to be extremely reliable, it is commonly used in many different applications requiring ample product passage. Available in versions with a plastic 5-position handle, stainless steel 4-position handle or with a millimetric regulation handle for precision measuring of fluid passage.

The VVF is a manual butterfly valve which cuts off and monitors fluids in the process flow by movements of opening and closing. Characterized by a simple and elegant design and engineered to be extremely reliable, it is commonly used in many different applications requiring ample product passage. Available in versions with a plastic 5-position handle, stainless steel 4-position handle or with a millimetric regulation handle for precision measuring of fluid passage.

BBZK is a modulating valve designed to regulate the flow rate and maintain a constant level, pressure or temperature value. Its special membrane actuator connected to the positioner allows partial opening and closing of the shutter, allowing intermediate flow rates and consequently pressure drop in the valve. Particularly suitable for applications where accurate control of the pressure, temperature and level measurements in the filling tank are required.

BBZK is a modulating valve designed to regulate the flow rate and maintain a constant level, pressure or temperature value. Its special membrane actuator connected to the positioner allows partial opening and closing of the shutter, allowing intermediate flow rates and consequently pressure drop in the valve. Particularly suitable for applications where accurate control of the pressure, temperature and level measurements in the filling tank are required.

The new J-Giotto Top® 360 has been designed to ensure effective control of the various movements of Bardiani Valvole valves. Each control unit can manage all the operations linked to valve functioning: in fact, both the position indicators (proximity switches) and the solenoid valves are installed inside the J-Giotto Top® 360, which can be quickly and easily installed on the top of the Bardiani valve actuator. Made from high-resistance materials, the reliability of the electrical components which make up the unit ensures the operator can safely monitor operation, also controllable in remote mode, by means of the illuminated indicators visible on all sides (360°).The high protection rating (IP67) against dust and liquid penetration ensures perfect operation of the various components even in the most arduous operating conditions.

The new J-Giotto Top® 360 has been designed to ensure effective control of the various movements of Bardiani Valvole valves. Each control unit can manage all the operations linked to valve functioning: in fact, both the position indicators (proximity switches) and the solenoid valves are installed inside the J-Giotto Top® 360, which can be quickly and easily installed on the top of the Bardiani valve actuator. Made from high-resistance materials, the reliability of the electrical components which make up the unit ensures the operator can safely monitor operation, also controllable in remote mode, by means of the illuminated indicators visible on all sides (360°).The high protection rating (IP67) against dust and liquid penetration ensures perfect operation of the various components even in the most arduous operating conditions.

To complete its production range and satisfy the increasingly demanding requirements of final users, AKOMAG also devotes itself to the design and manufacturing of “turnkey” systems.

To complete its production range and satisfy the increasingly demanding requirements of final users, AKOMAG also devotes itself to the design and manufacturing of “turnkey” systems.

COMBI, designed following different small users indications with low production (family winery, micro beer, etc.) it offers a great versatility and can adapt to the most varied range of requirements.

COMBI, designed following different small users indications with low production (family winery, micro beer, etc.) it offers a great versatility and can adapt to the most varied range of requirements.

Production of PET Bottles

Production of PET Bottles

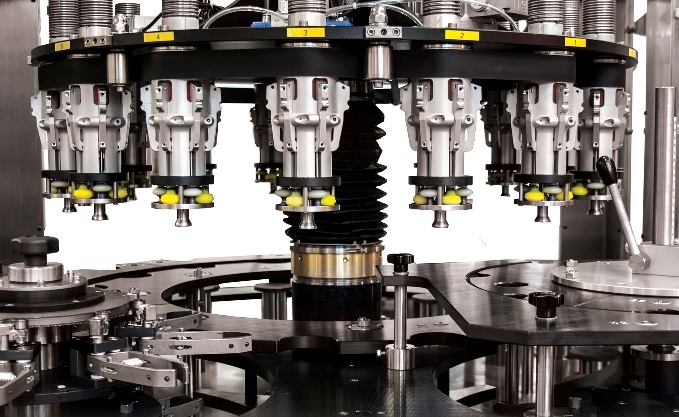

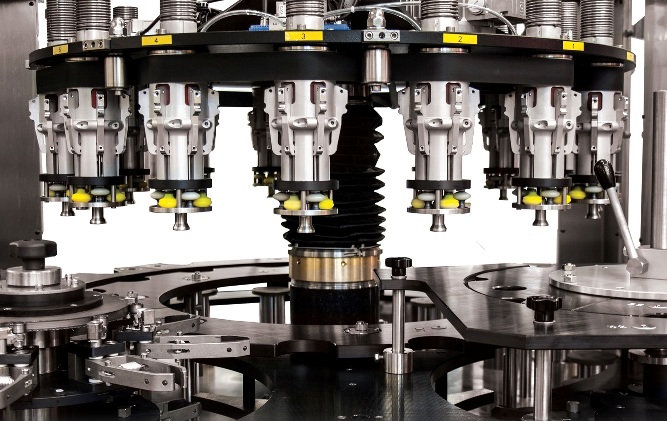

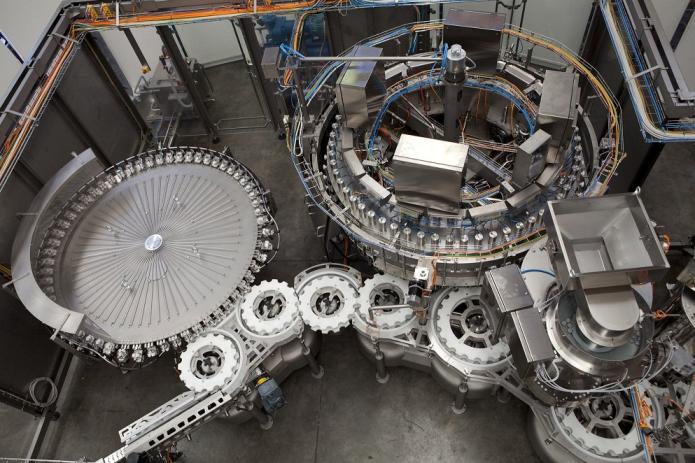

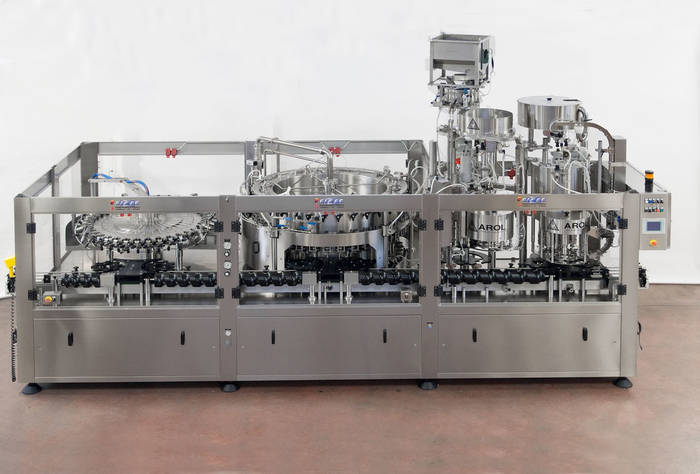

A New generation of Arol Cappers, completely washable, easy to sanitize, from the upper cam mounting plate to the bottom base.

A New generation of Arol Cappers, completely washable, easy to sanitize, from the upper cam mounting plate to the bottom base.

Ave Technologies - Della Toffola Group present an important innovation: the SWAN filling system.

Ave Technologies - Della Toffola Group present an important innovation: the SWAN filling system.

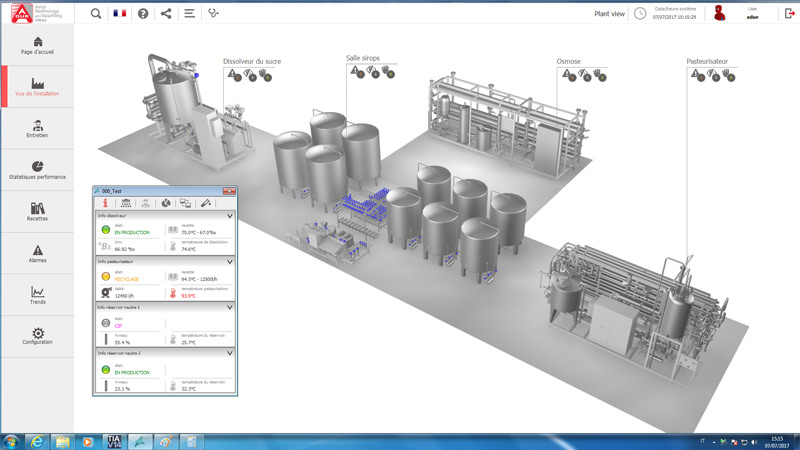

PREMIX units are designed to assure carbonated soft beverages and non-carbonated soft beverages preparation by process water deaeration, mixing with aromatized syrup and carbonation with CO2 injection.

PREMIX units are designed to assure carbonated soft beverages and non-carbonated soft beverages preparation by process water deaeration, mixing with aromatized syrup and carbonation with CO2 injection.

jpg.jpg)

jpg.jpg)

jpg.jpg)

.png)

jpg.jpg)

jpg.jpg)

MASTER PET RS/SC model is based on counter-pressure filling technology, suitable to fill still and carbonated beverages dedicated to PET bottles.

MASTER PET RS/SC model is based on counter-pressure filling technology, suitable to fill still and carbonated beverages dedicated to PET bottles.

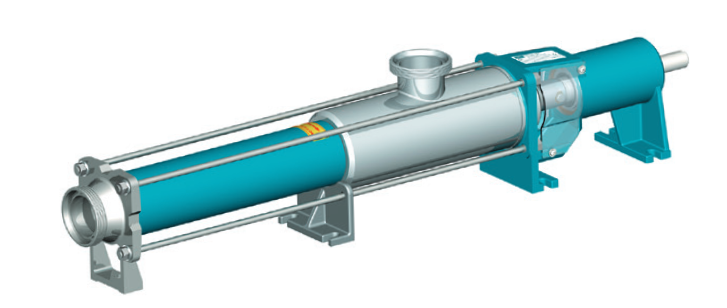

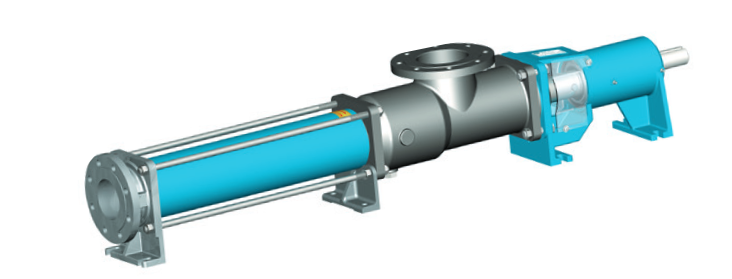

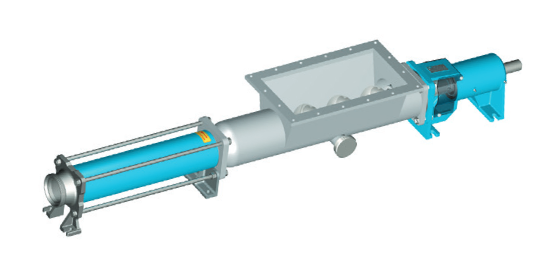

The Chemetator is a scraped surface heat exchanger ideal for many applications in the food, pharmaceutical and chemical industries. During operation, the product flows through a jacketed cylinder containing a rotating central shaft on which the scraper blades are mounted. These rotating blades continuously remove the product from the heat transfer tube.

The Chemetator is a scraped surface heat exchanger ideal for many applications in the food, pharmaceutical and chemical industries. During operation, the product flows through a jacketed cylinder containing a rotating central shaft on which the scraper blades are mounted. These rotating blades continuously remove the product from the heat transfer tube.

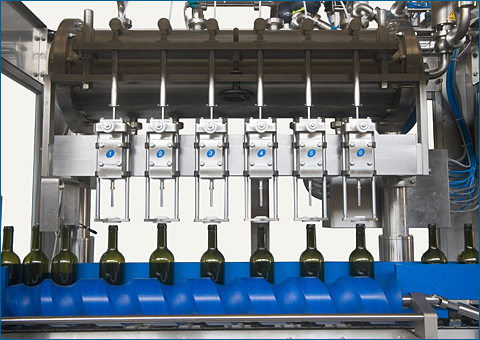

MONDIAL“ series fillers are suitable for bottling products such as wines, liqueurs, spirits, vinegar, fruit juice, oils, still water and other non-carbonated liquids in cylindrical and/or shaped containers made of glass, plastic or other material.

MONDIAL“ series fillers are suitable for bottling products such as wines, liqueurs, spirits, vinegar, fruit juice, oils, still water and other non-carbonated liquids in cylindrical and/or shaped containers made of glass, plastic or other material.

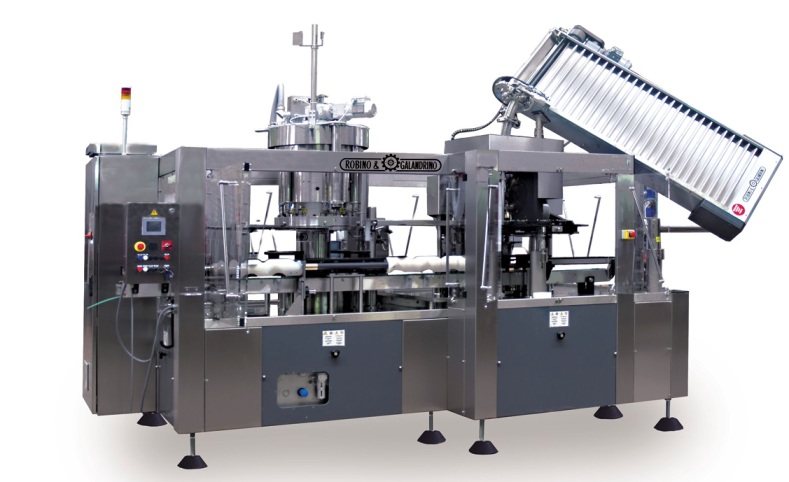

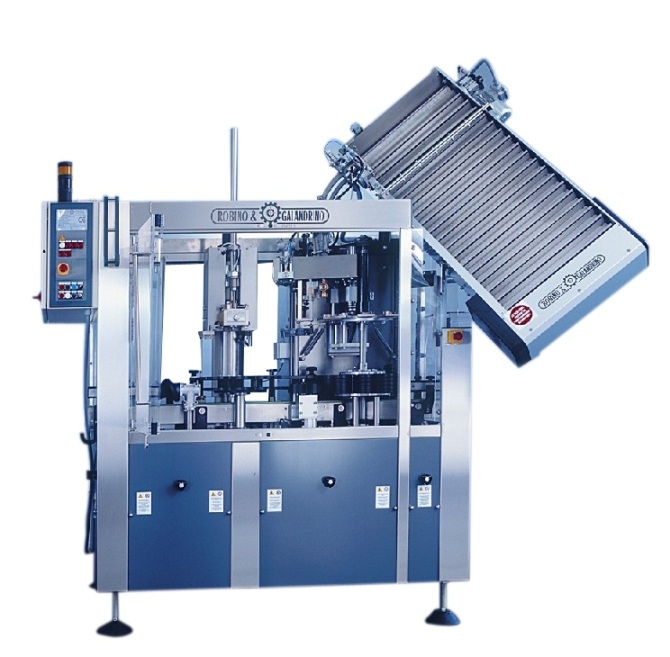

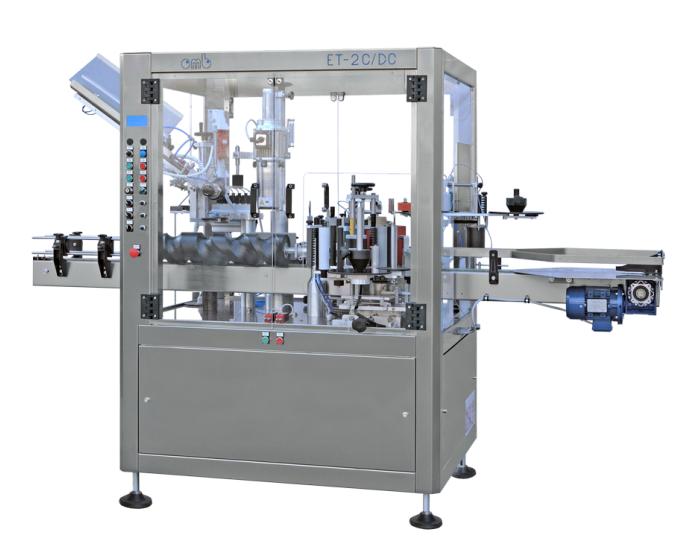

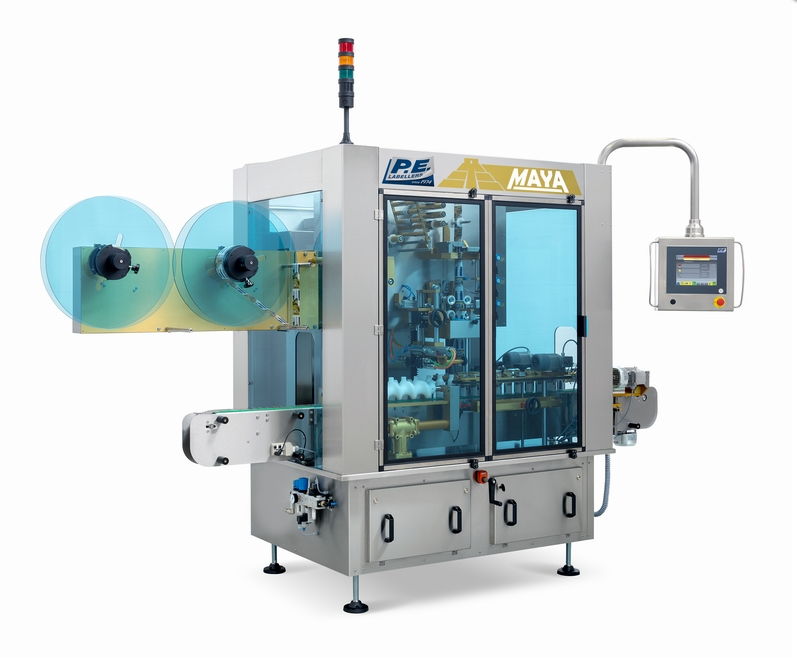

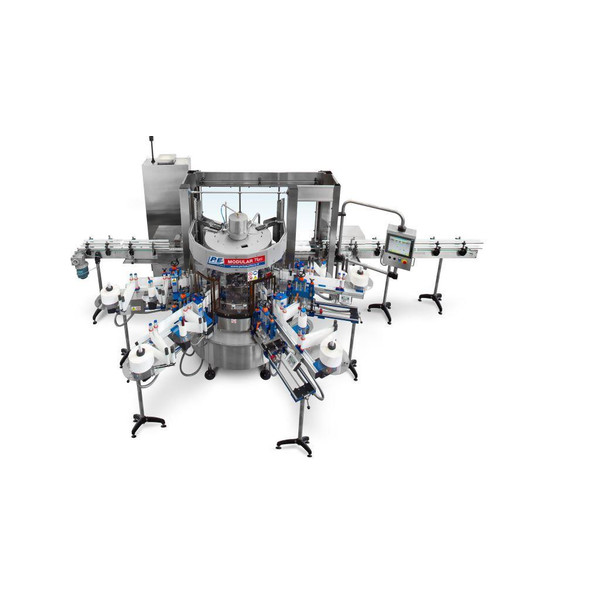

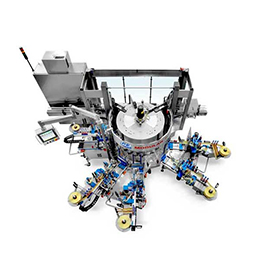

AUTOMATIC LABELING MACHINES: can be fitted with wet glue or self-adhesive labelling stations.

AUTOMATIC LABELING MACHINES: can be fitted with wet glue or self-adhesive labelling stations.

The isobaric filling machines in the “AMERICA“ range are designed for bottling fizzy liquids such as sparkling wines, spumanti and champagne, but are also suitable for particularly delicate still wines, or other types of fizzy drinks or beer, in containers made of glass, plastic or other materials.

The isobaric filling machines in the “AMERICA“ range are designed for bottling fizzy liquids such as sparkling wines, spumanti and champagne, but are also suitable for particularly delicate still wines, or other types of fizzy drinks or beer, in containers made of glass, plastic or other materials.

The Flash pasteurizer is used for the processing of beer destined to keg filling. The pasteurization of the product is obtained at 71°C approximately. The product proceeding from the cellar at the storage temperature is heated by means of a first intersection with the beer coming from the heat transfer surface area and then a second intersection with the hot water circulating in the heating zone of the plate heat exchanger. Vice versa, after the pasteurization the hot beer is submitted to a first substantial cooling thanks to the intersection with the cold beer proceeding from the cellar; it finally reaches the ideal storage temperature passing through the cooling area of the plate heat exchanger. Then the beer is sent out to the buffer tank and eventually to the filling machine. Some special cycles have been introduced in order to carry out the cleaning of pipes and buffer tank. The conductivity detector allows the pasteurizer to determine which kind of liquid is flowing through the pipes in real time.

The Flash pasteurizer is used for the processing of beer destined to keg filling. The pasteurization of the product is obtained at 71°C approximately. The product proceeding from the cellar at the storage temperature is heated by means of a first intersection with the beer coming from the heat transfer surface area and then a second intersection with the hot water circulating in the heating zone of the plate heat exchanger. Vice versa, after the pasteurization the hot beer is submitted to a first substantial cooling thanks to the intersection with the cold beer proceeding from the cellar; it finally reaches the ideal storage temperature passing through the cooling area of the plate heat exchanger. Then the beer is sent out to the buffer tank and eventually to the filling machine. Some special cycles have been introduced in order to carry out the cleaning of pipes and buffer tank. The conductivity detector allows the pasteurizer to determine which kind of liquid is flowing through the pipes in real time.

Depending on the required configuration complexity, the CIP plant can carry out the cleaning of the pipes connecting the cellar to the filling machine or include in the cleaning process the whole of the machines installed between the cellar and the filler (Flash pasteurizers, premix, carbonators, etc…). The number of tanks and the automation level of the system can vary according to the customers’ needs: either the whole of the operations are manually controlled by the operator or a complex system automatically controls cleaning solution level, concentration, temperature and flow rate, cycle time parameters and discharge or recovery of the return solutions by means of a PLC.

Depending on the required configuration complexity, the CIP plant can carry out the cleaning of the pipes connecting the cellar to the filling machine or include in the cleaning process the whole of the machines installed between the cellar and the filler (Flash pasteurizers, premix, carbonators, etc…). The number of tanks and the automation level of the system can vary according to the customers’ needs: either the whole of the operations are manually controlled by the operator or a complex system automatically controls cleaning solution level, concentration, temperature and flow rate, cycle time parameters and discharge or recovery of the return solutions by means of a PLC.

.png)

Technical info:

Technical info:

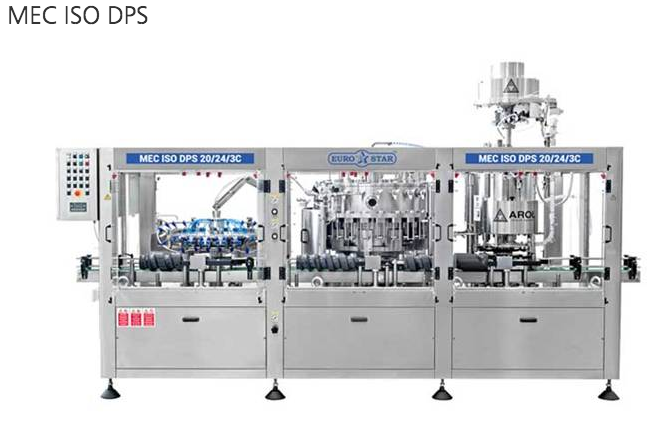

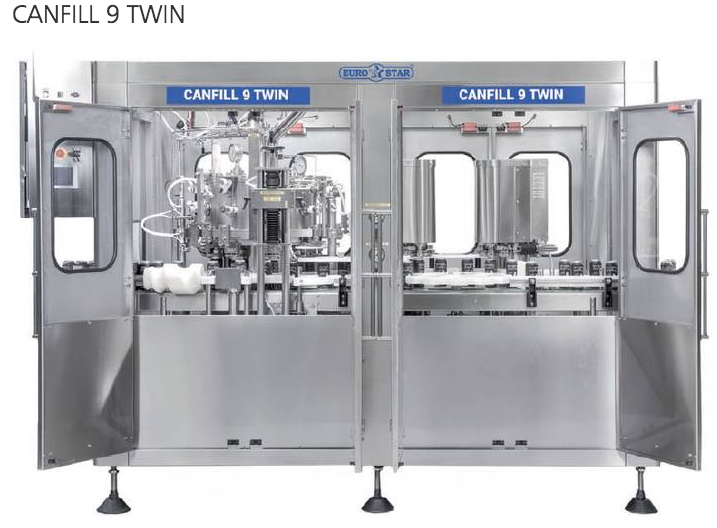

Counter pressure (mechanic)

Counter pressure (mechanic)

ISOBARIC CAN FILLING & SEAMING SYSTEM

ISOBARIC CAN FILLING & SEAMING SYSTEM

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

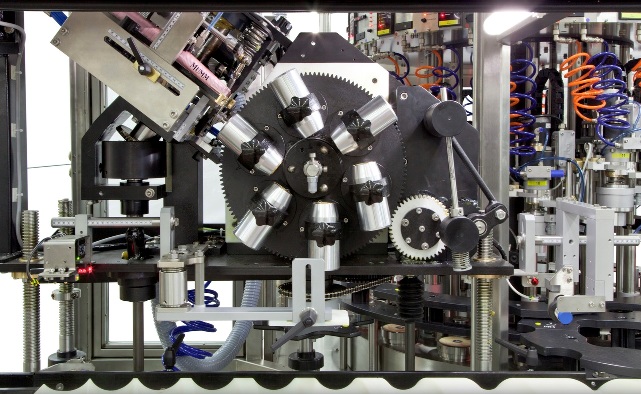

.jpg) The etymology of the word monoblock immediately conveys a clear idea of what it means; a set of machines forming part of the same block.

The etymology of the word monoblock immediately conveys a clear idea of what it means; a set of machines forming part of the same block..jpg)

.png) Isobaric units are able to work with all products containing co2 in higher or lower quantities. Isobaric machines can also be used for products containing no co2, so-called still products.

Isobaric units are able to work with all products containing co2 in higher or lower quantities. Isobaric machines can also be used for products containing no co2, so-called still products..png) The ps valve pre-expels the air contained in the bottle before the pressure compensation by means of gas counter pressure. The more complicated but also more complete valves are the sl, psl, dps and dpsl where l stands for final levelling; these are particularly suitable for necks that are difficult to equalize with the isobaric machine, as in the case of the bordeaux bottle; d stands for double pre-expulsion where injection between the first and the second air pre-expulsion is through an external clean gas circuit. In the mechanical version, all these operations are controlled by cams.

The ps valve pre-expels the air contained in the bottle before the pressure compensation by means of gas counter pressure. The more complicated but also more complete valves are the sl, psl, dps and dpsl where l stands for final levelling; these are particularly suitable for necks that are difficult to equalize with the isobaric machine, as in the case of the bordeaux bottle; d stands for double pre-expulsion where injection between the first and the second air pre-expulsion is through an external clean gas circuit. In the mechanical version, all these operations are controlled by cams.

.jpg) The fimer high-vacuum filling machine is designed specifically for particularly dense products filled in glass containers or in any case resistant material, such as for example, miniature pet bottles.

The fimer high-vacuum filling machine is designed specifically for particularly dense products filled in glass containers or in any case resistant material, such as for example, miniature pet bottles..jpg) The high-vacuum filling machine works thanks to a pressure difference. Atmospheric pressure in the filling machine tank, in which the product is located, and negative pressure in the bottle thanks to a vacuum pump that draws directly on the bottle’s air return circuit. Thanks to this pressure delta, the product contained in the tank is sucked up directly by the bottle.

The high-vacuum filling machine works thanks to a pressure difference. Atmospheric pressure in the filling machine tank, in which the product is located, and negative pressure in the bottle thanks to a vacuum pump that draws directly on the bottle’s air return circuit. Thanks to this pressure delta, the product contained in the tank is sucked up directly by the bottle.

.jpg) The filling unit is the only machine that has direct contact with the finished product and therefore must be conceived, designed and built so it provides utmost reliability in terms of product guarantee. It must maintain product characteristics during the actual filling operation but must also be easily washable and also easily sterilized when in contact with products particularly sensitive to pollution.

The filling unit is the only machine that has direct contact with the finished product and therefore must be conceived, designed and built so it provides utmost reliability in terms of product guarantee. It must maintain product characteristics during the actual filling operation but must also be easily washable and also easily sterilized when in contact with products particularly sensitive to pollution..jpg) Fimer filling machines include gravity or light vacuum and isobaric machines – both traditional and electro-pneumatic versions – volumetric machines, high vacuum or light pressure machines, electronic machines with flow meters that can be magnetic or inertial.

Fimer filling machines include gravity or light vacuum and isobaric machines – both traditional and electro-pneumatic versions – volumetric machines, high vacuum or light pressure machines, electronic machines with flow meters that can be magnetic or inertial.

.jpg) Experience acquired in the field of bottling plants has also enabled fimer to be a prime contractor for the supply of complete plants.

Experience acquired in the field of bottling plants has also enabled fimer to be a prime contractor for the supply of complete plants..jpg)

Continuous brewing, just-in-time production technology and digitalization: “Brewery 4.0”

Continuous brewing, just-in-time production technology and digitalization: “Brewery 4.0”

Launch of the highest performance high-pressure homogenizer in the world

Launch of the highest performance high-pressure homogenizer in the world

The sprayer Ginox, versatile and easy to install in any pool or tank, offers the opportunity to constantly wet the marcduring fermentation and thus to avoid oxidation, both permorme the function of milling.

The sprayer Ginox, versatile and easy to install in any pool or tank, offers the opportunity to constantly wet the marcduring fermentation and thus to avoid oxidation, both permorme the function of milling.

The 1 hl. o 2,5 hl. Pocket-Bräu Brewhouse is the ideal model for restaurants and farms that want to offer their customers a small beer production. Also suitable for those ready to take their first steps in this sector, this plant can be useful for testing new recipes or training students in courses organized by schools or Universities of the brewing sector.

The 1 hl. o 2,5 hl. Pocket-Bräu Brewhouse is the ideal model for restaurants and farms that want to offer their customers a small beer production. Also suitable for those ready to take their first steps in this sector, this plant can be useful for testing new recipes or training students in courses organized by schools or Universities of the brewing sector.

The 2.5, 5 or 10 hl Compact-Bräu Brewhouse is the ideal model for microbreweries and brewpubs that want to enter into the craft beer world, but also for wine bars, farms, beverage manufacturers and restaurant owners looking to diversify an existing business.

The 2.5, 5 or 10 hl Compact-Bräu Brewhouse is the ideal model for microbreweries and brewpubs that want to enter into the craft beer world, but also for wine bars, farms, beverage manufacturers and restaurant owners looking to diversify an existing business.

.png) The new Nimos generatos can be seen as an evolution of traditional systems using the PSA principle (Pressure Swing Adsorption) which allows a constant production of Nitrogen from compressed air.

The new Nimos generatos can be seen as an evolution of traditional systems using the PSA principle (Pressure Swing Adsorption) which allows a constant production of Nitrogen from compressed air..png) Nitrogen in Oenology

Nitrogen in Oenology

spirits, and so on…) into glass bottles.

spirits, and so on…) into glass bottles. During filling process, by gravity, the product is deflected towards the bottle inner side so to avoid any turbulences and the gas/air contained inside the bottle returns to product tank upper side.

During filling process, by gravity, the product is deflected towards the bottle inner side so to avoid any turbulences and the gas/air contained inside the bottle returns to product tank upper side.

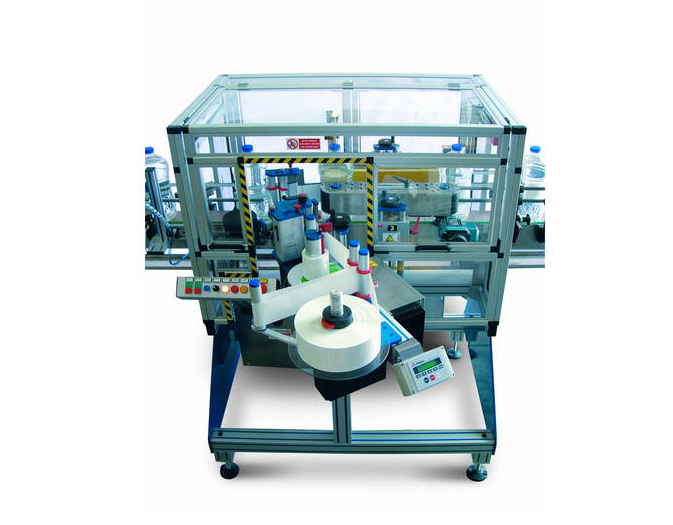

Automatic linear labelling machine for attaching self-adhesive labels to cylindrical bottles or containers of wine, beverages or foodstuffs in general, consisting of: a body labelling station (with the opportunity for attaching a back label from the same roll); forward feed; fixed pick-up plate; stepping motor. The linear labelling machine is delivered ready for including in a bottling line and equipped for a given type of capsule and bottle or cylindrical container. Made entirely of stainless steel, it is solid and strong, and based on an advanced technology, achieving a high output. Designed for maximum operator safety and ease of use, it is quick to adjust and complete with safety shields. At the customer's request, it can be adapted for use with stiff paper or cardboard containers, and cardboard boxes.

Automatic linear labelling machine for attaching self-adhesive labels to cylindrical bottles or containers of wine, beverages or foodstuffs in general, consisting of: a body labelling station (with the opportunity for attaching a back label from the same roll); forward feed; fixed pick-up plate; stepping motor. The linear labelling machine is delivered ready for including in a bottling line and equipped for a given type of capsule and bottle or cylindrical container. Made entirely of stainless steel, it is solid and strong, and based on an advanced technology, achieving a high output. Designed for maximum operator safety and ease of use, it is quick to adjust and complete with safety shields. At the customer's request, it can be adapted for use with stiff paper or cardboard containers, and cardboard boxes.

SLEEVER, SLEEVE APPLICATOR WITH THERMAL SHRINKING TUNNEL

SLEEVER, SLEEVE APPLICATOR WITH THERMAL SHRINKING TUNNEL

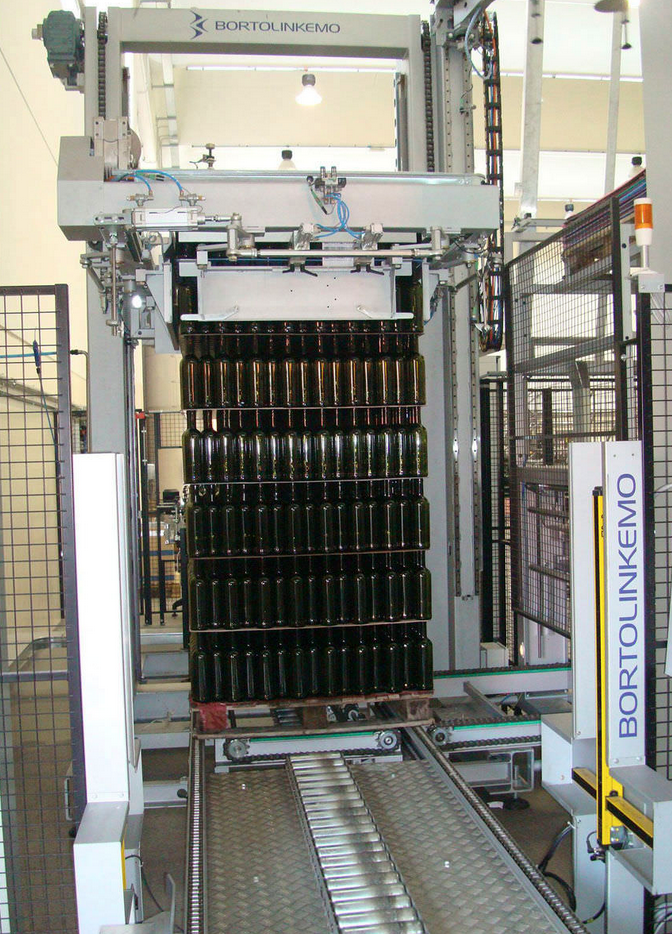

Automatic stretch wrapping machine with rotating ring for high productivity. New generation wrapping machine for wrapping and stabilising loads on pallets with stretch film, Genesis Cube stems from the development of previous Robopac Sistemi ring machines and it also operates without sliding electrical contacts, guaranteeing safety, overall weight reduction and balance of the rotating masses.

Automatic stretch wrapping machine with rotating ring for high productivity. New generation wrapping machine for wrapping and stabilising loads on pallets with stretch film, Genesis Cube stems from the development of previous Robopac Sistemi ring machines and it also operates without sliding electrical contacts, guaranteeing safety, overall weight reduction and balance of the rotating masses.

Monoblock for Bag in Box cartons forming, bag filling and hot glue carton sealing.

Monoblock for Bag in Box cartons forming, bag filling and hot glue carton sealing.

The Kube labeling machine is suitable for different fields: wine, food, pharmaceutical and detergents in general. The machines are suitable for packaging lines from 1,000 to 25,000 containers/hour with the application of adhesive labels, cold glue, hot melt glue or mixed.

The Kube labeling machine is suitable for different fields: wine, food, pharmaceutical and detergents in general. The machines are suitable for packaging lines from 1,000 to 25,000 containers/hour with the application of adhesive labels, cold glue, hot melt glue or mixed.

The SFR EVO3 range of stretch blow molding machines improves output rates and performance

The SFR EVO3 range of stretch blow molding machines improves output rates and performance Thanks to the SIPA rotary SFR’s unique and optimum oven ventilation system and simple and slow preform handling kinetics, the handling of light and delicate neck finishes remains easy even at such high production rates.

Thanks to the SIPA rotary SFR’s unique and optimum oven ventilation system and simple and slow preform handling kinetics, the handling of light and delicate neck finishes remains easy even at such high production rates.

A new, extremely innovative and flexible platform, which takes the standard Sipa technologies to the highest level currently available on the market.

A new, extremely innovative and flexible platform, which takes the standard Sipa technologies to the highest level currently available on the market.

.jpg)

.jpg)

The new ERGON range of automatic packers is based on design choices inspired by key concepts such as ergonomics, technology, sturdiness and modularity, masterfully blended to mark a new, significant evolution in the history of SMI products.

The new ERGON range of automatic packers is based on design choices inspired by key concepts such as ergonomics, technology, sturdiness and modularity, masterfully blended to mark a new, significant evolution in the history of SMI products.

Sistema integrato

Sistema integrato

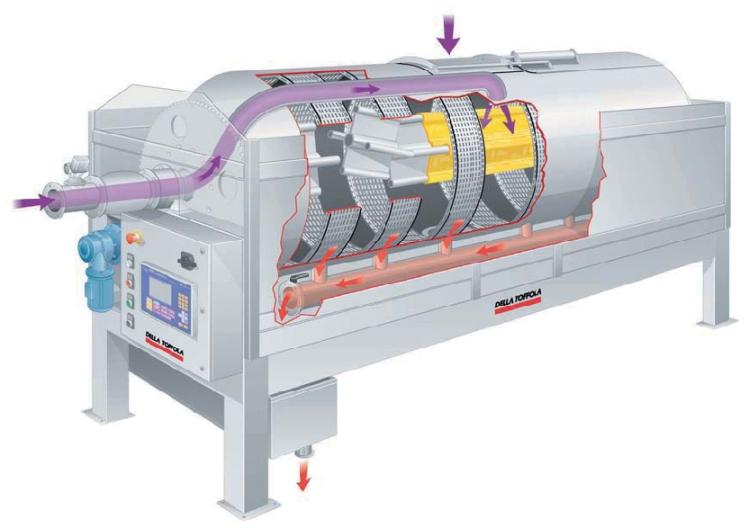

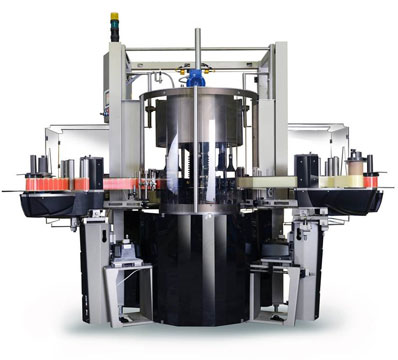

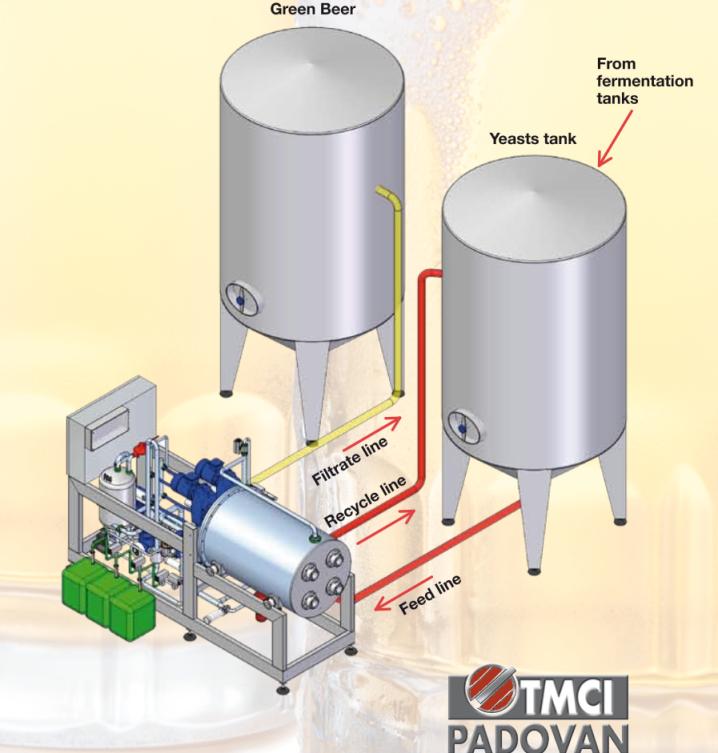

Crossflow filter

Crossflow filter

Revolutionary rotary crossflow filter: double performance, alf the costs!

Revolutionary rotary crossflow filter: double performance, alf the costs!

Automatic carton packer with 2 movimentation axles, conform to receive and organize in a suitable way the boxes coming from the filling section, pick them up according to a proper quantity and insert them into the cartons or cases. Manufactured for working with a wide range of products in small areas.

Automatic carton packer with 2 movimentation axles, conform to receive and organize in a suitable way the boxes coming from the filling section, pick them up according to a proper quantity and insert them into the cartons or cases. Manufactured for working with a wide range of products in small areas.

The PADOVAN Tunnels are manufactured to ensure the suitable thermal treatment to the products already filled in containers of various sizes and capacities.

The PADOVAN Tunnels are manufactured to ensure the suitable thermal treatment to the products already filled in containers of various sizes and capacities.

Fermenters

Fermenters

Brewpubs

Brewpubs

Features

Features

The all-in-one solution for small and medium producers

The all-in-one solution for small and medium producers

Daniele Toni

Daniele Toni